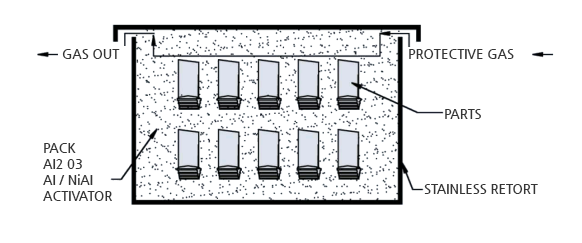

Pack Process

Components are packed in mixed powder, called pack, mixed at specific ratio of metallic powder and activator, inert powder. These are then heated inside a furnace at inert or reduction gas atmosphere. The source metal reacts with an activator on heating to form gaseous halide compound. This gas is transferred to substrate surface by gradient of activity, ie, gradient of partial pressure. The gas decomposes at the substrate surface depositing coating element and releasing the halogen activator

Advantage

- Simple process

- Easy to control coating quality

Disadvantage

- High energy consumption during diffusion heat treatment

- Coating waste

Example

- ALPAK, CODEP