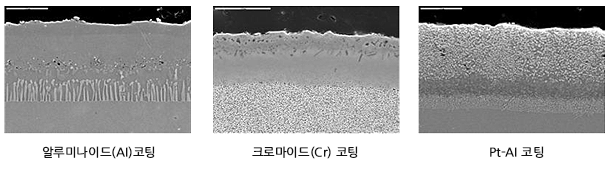

Diffusion Coating

One of protective coatings to increase high temperature oxidation and hot corrosion resistance. During coating, intermetallic compounds are formed from base metal(Ni, Co, Fe) and coating element(Al, Cr, Si). The coating protects base metal by selective oxidation of coating element during service. Aluminide(Al) coating is applied to increase high temperature oxidation resistance at service temperature above 850¡É, Chromide(Cr) and Silicide(Si) coatings are applied to increase hot corrosion resistance at service temperature below 850¡É. Co-deposition of Al-Cr or Al-Si is applied to increase hot corrosion resistance of simple aluminide coating.

Advantage

- Dense coating without porosity, crack

- High bond strength by diffused layer with substrate

- Available on complex configuration and narrow cooling passage

Disadvantage

- Limited coating element and coating thickness

- Large equipment for large component

Comparison of Diffusion Coating

| Proces |

Proces |

Applicable

substrate |

Coating

characteristics |

Coating method |

| Slurry |

Pack |

Vapor |

| Aluminizing |

Al |

Fe-base, Ni-base,Co-base |

High temperature oxidation resistance

Usable up to 1100¡É |

¡Û |

¡Û |

¡Û |

| Chromizing |

Cr |

Fe-base, Ni-base |

Hot corrosion resistance

Usable up to 900 ¡É |

¡â |

¡Û |

¡Û |

| Pt-luminizing |

Pt + Al |

Ni-base |

Oxidation & hot corrosion resistance

Resist 3~4 times than simple aluminzing |

¡â |

¡Û |

¡Û |

| Composite |

Al + Cr Al + Si |

Fe-base, Ni-base |

Oxidation & hot corrosion resistance |

¡Û |

¡Û |

¡â |

| Boronizing |

B |

Fe-base, Ni-base,Co-base |

Wear resistance

Hardness 1800¡2000 Hv |

¡â |

¡Û |

¡â |